- Tel: +44(0)1684 273164

- Email: enquiry@ingridwest.co.uk

|

Specifications can be modified according to customer requirements.

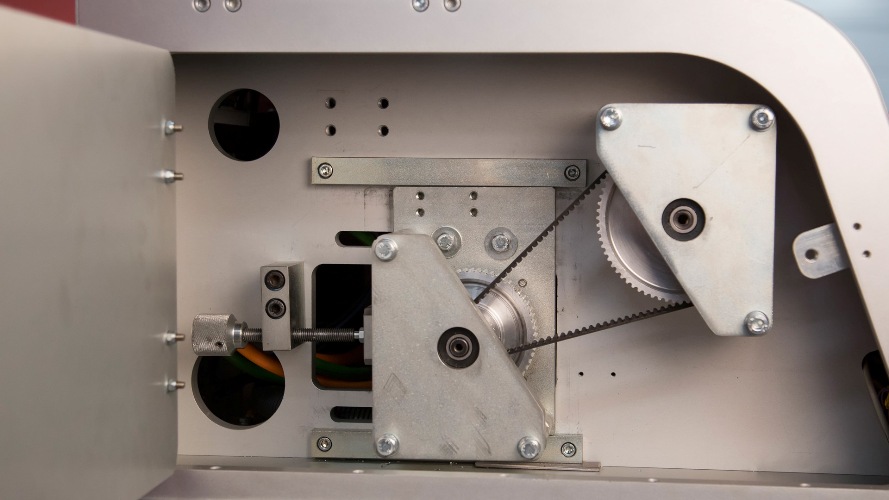

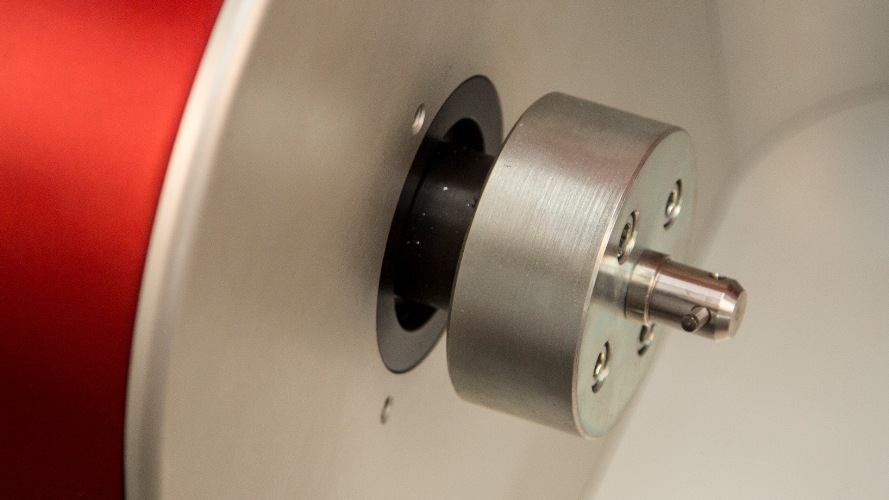

* if ER25 collet chuck used > 252mm// If Ø160 used > 470 Torque and Speed Single speed range Direct Drive

Three speed ranges- fast belt changeover

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

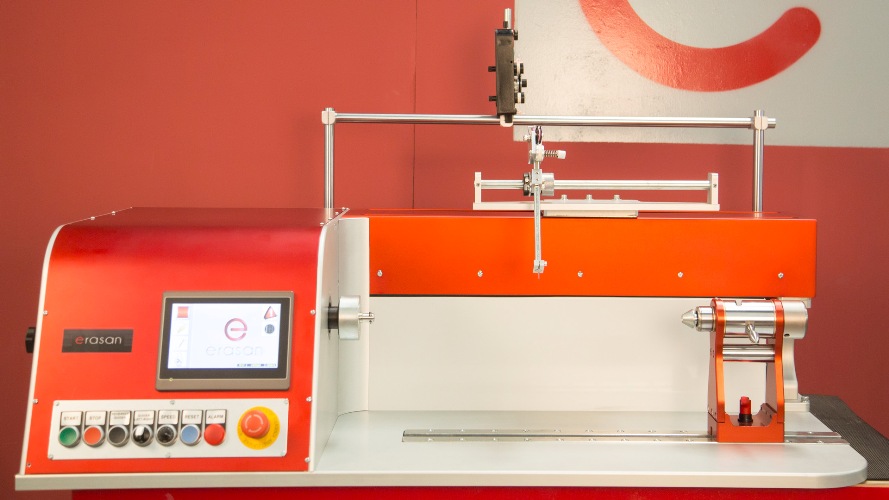

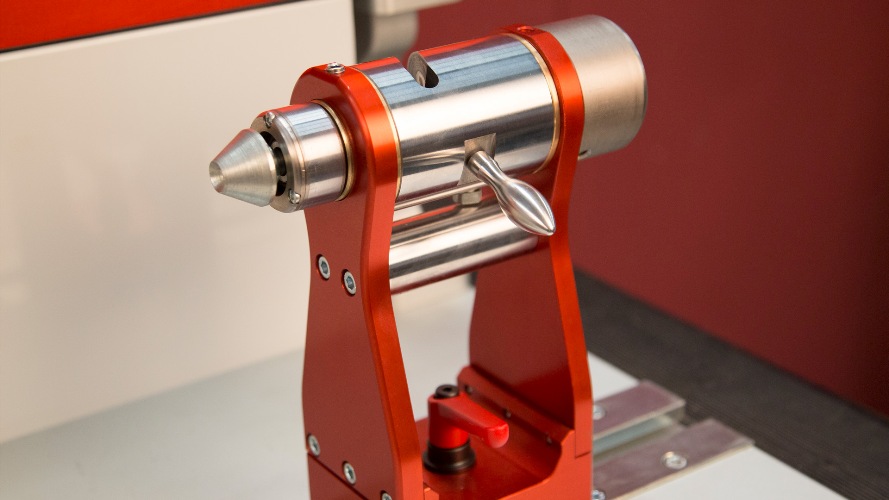

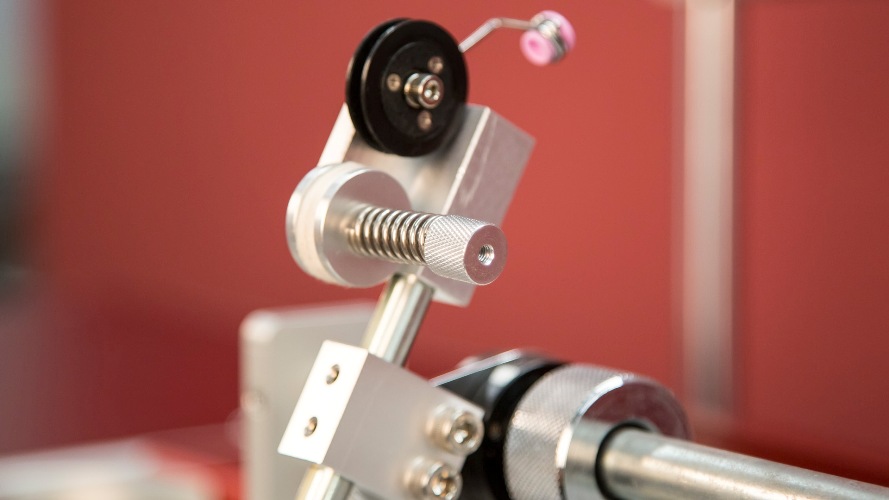

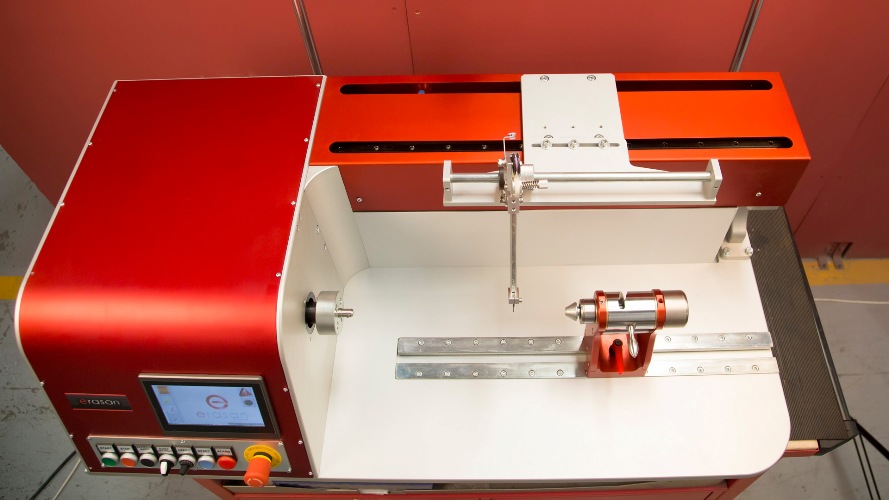

E-300 - Small sized bench Winding Machine; equipped with: -

The applications of this machine is intended for the manufacture of solenoids, reactances, transformers, with capacity to make multiple windings and even distribution and power transformers.

Gallery

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||