- Tel: +44(0)1684 273164

- Email: enquiry@ingridwest.co.uk

|

Specifications can be modified according to customer requirements.

* There are many version of this machine, can be customised to your requirements. |

|||||||||||||||||||||||||||||||||

|

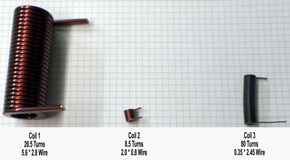

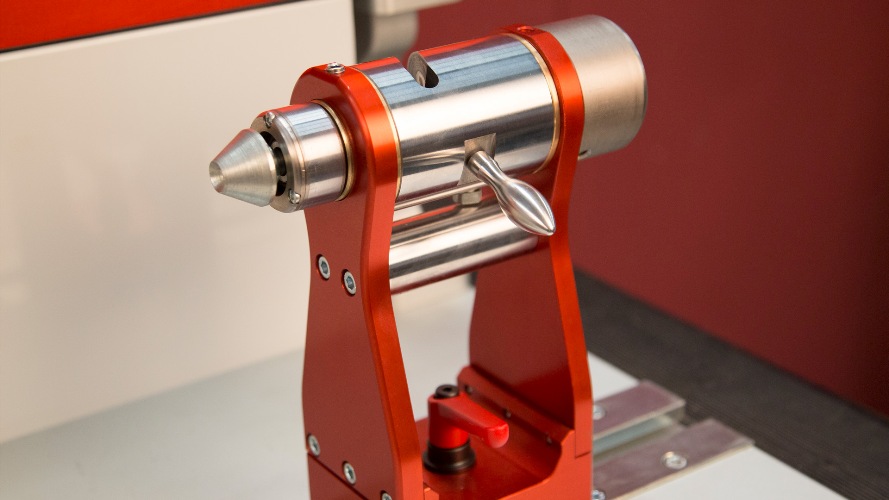

E-300 - Small sized bench Winding Machine; equipped with: -

The edge machine is really a customised solution for round core (ID) single layer coils... In the winding industry there are a lot of new products using flat wire edge wound coils. each project is virtually a one off... as technically they require a completely different solution depending on the tasks. The basic machine is specially designed construction 2 axis winder, more power / torque is required that standard winding. For leg positional accuracy, we incorporate programmable rotational resolution <0.36deg, the rest is tooling and configuration of guiders tailstock, special start lead clamping systems etc... made by our own in-house team of experts. This machine pushed the boundaries of what is achievable in relation to the aspect ratio of wire height Vs wire width and wire height Vs coil ID, whilst reducing the trapezoidal effect to a minimum ! The colour touch screen provides a simple and intuitive programming system with graphical interface and on-screen help, allowing even the most complex windings to be programmed in short periods of time in the user's choice of language. A foot pedal is provided so that the operator can control the machine manually if required.

Gallery

|

|||||||||||||||||||||||||||||||||